- Home

- /

- Products

- /

- Drying test

- /

- Gradient Oven Model 432 Smart - ERICHSEN

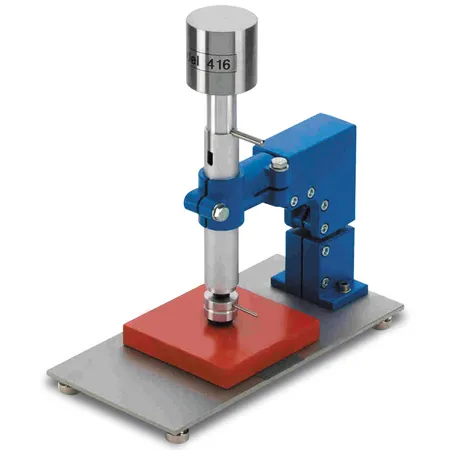

Gradient Oven Model 432 Smart - ERICHSEN

For evaluating drying and baking behaviours, testing chemical resistance, up to 320 °C. Delivered and supported by Cromocol.

Get a Quote

The Model 432 Smart I gradient oven, engineered by ERICHSEN, serves as an advanced solution for evaluating the drying and baking behavior of coatings, resins, and plastics. This device simulates production processes accurately, enabling predictions on paint reactions across various temperatures. It’s designed for applications in R&D, quality control, and manufacturing processes where chemical resistance testing is critical.

With its ability to test coatings up to 250°C and facilitate the testing of two different lacquers on the same sheet, it provides a valuable tool for automotive paint manufacturers and other industries facing aggressive environmental factors.

The oven’s capability for a needs-based process optimization, by simulating actual stove enameling conditions on a laboratory scale, offers significant time and cost savings. Its precision and repeatability ensure reliable limit value determinations, critical for maintaining high-quality standards in coating systems.

Furthermore, the integration of a microprocessor-controlled heating bench with 45 isolated elements allows for seamless creation of linear or step temperature gradients, accommodating a wide range of test scenarios. The Model 432 Smart I addresses the need for a versatile, efficient, and effective laboratory instrument in materials testing and quality assurance.

Technical Specifications

- Drive: Electric

- Weight: approx. 103 kg

- Voltage: 230 V, 50/60 Hz

- Accuracy: control accuracy of the heating elements: < ±2 °C (±3.6 °F) surface temperatures on 0.8 mm test panels from element 3 up to 43: up to 200° ± 2 °C (up to 392 ° ± 3.6 °F) // up to 250 ° ± 3 °C (up to 482 ° ± 5.4 °F) // up to 320 ° ±5 °C (up to 608 ° ±9.0 °F) // Measured under specified test conditions

- Baking Time: in sec. and min.

- Test Surface: 500 x 70 mm (19.6 x 2.7 in)

- Heat-Up-Speed: 2 °C up to 30 °C/min, programmable (3.6 °F/min up to 54 °F/min)

- Step Gradient: with 2, 3 or 4 steps: max. temperature difference between two steps: 50 °C (90 °F)

- Holding Device: reciprocates automatically (approx. 160 N) for insertion and removal of panel

- Heating Surface: 520 x 100 mm (20.4 x 3.9 in)

- Linear Gradient: max. temperature difference between 30 and 250(320) °C: 100 °C\; 86 and 482 (608) °F: 180 °F

- Heating Elements: 45 St.

- Power Consumption: 3400 VA

- Dimensions (HxWxD): approx. 470 x 860 x 585 mm (18 x 34 x 22 in)

- Dimensions (exterior): approx. 870 x 655 x 500 mm (W x D x H)

- Operating temperature: 30 °C - 250 °C

- Portable / Stationary: Stationary

- Test Benches / Test Trail: 45

Documents & Downloads

Frequently Asked Questions

What applications is the Model 432 Smart I gradient oven designed for?

What is the maximum temperature the gradient oven can test coatings up to?

Can the Model 432 Smart I test different lacquers on the same sheet?

How does the heating system work in the Model 432 Smart I gradient oven?

What are the technical specifications of the Model 432 Smart I?

Is the Gradient Oven Model 432 Smart I portable?

What benefits does the Model 432 Smart I offer to automotive paint manufacturers?

Request a quote for Gradient Oven Model 432 Smart - ERICHSEN

Fill out the form, give us a call or send an email and we will contact you as soon as possible.